Sustainability

Eco-Friendly Materials and Sustainable Solutions.

Eco-Friendly Materials and Sustainable Solutions.

"Nature is the great visible engine of creativity, against which all other creative efforts are measured.” - Terence McKenna

Our eco-solutions are the result of extensive research and development into sustainable materials and manufacturing processes. We focus on minimising environmental impact at every stage of production, from sourcing raw materials to the finished product. By incorporating recycled and renewable resources, we aim to reduce waste and lower our carbon footprint. We are committed to providing effective, high-quality products that align with our environmental values.

Furthermore, our exclusive 4-year guarantee is a testament to the trust we have in our equipment. Above all, we believe that having gear that lasts for many years is the single most important factor in tackling sustainability in snowboard production.

Some of our boards are built with a natural bamboo topsheet. We also use it as part of some of our wood cores. Bamboo is one of the fastest-growing plants in the world. Its capacity to renew itself quickly makes it the ideal candidate in our quest for low-carbon footprint materials. Naturally resilient, snappy and light, it is the perfect material to make amazing snowboards with great pop, reduced vibrations and unmatched control. At Borealis, our bamboo veneers are protected with 7 layers of matte or glossy voc-free and water-based lacquer, ensuring maximum durability.

To bond all the materials that make our snowboards, we use a Zero-VOC Resin which rejects 0% of Volatile Organic Compounds, commonly called toxic vapours. Traditonal epoxy resin is the biggest polluting factor in snowboards construction. This alternative is essential to protect the worker making your board whilst keeping all the strength and durability required to built the most durable snowboards on the planet.

All our wood cores are made using sustainably-harvested wood, which means the forests it comes from are socially, economically and environmentally viable, allowing today's and long-term needs to be met durably.

Plant-based bioplastic (50%) ultra-thin textured sheets used on splitboards They are super resilient and limit the adherence of snow for a smoother, lighter ride.

The topsheets of our boards are printed using two different techniques: sublimation and UV printing. Both processes are water-based, eliminating the need for toxic solvent-based solutions. The lacquer used on bamboo topsheets is also water-based.

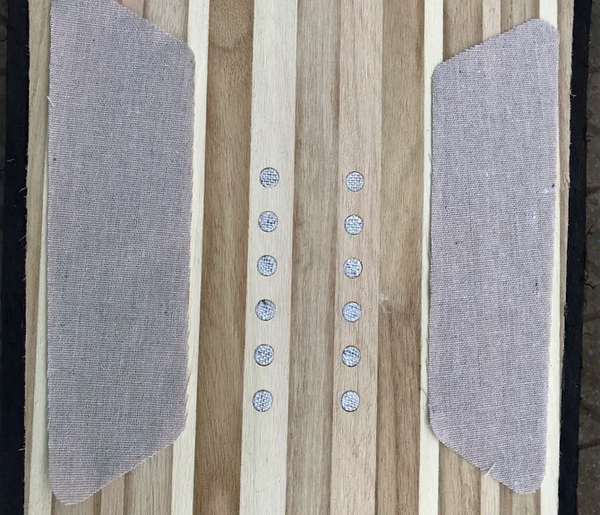

We use natural flax pads to counter binding impacts and reduce vibration on all models with bamboo or fully opaque topsheets. This is an eco-friendly alternative to fiberglass pads.

Maritime transport is the means of transportation with the least carbon footprint. All our boards are shipped by boat from the factory's nearest harbour in Marseille, about 100km south of the Borealis Headquarters in Avignon.

Our headquarters are connected to a 100% green energy provider ensuring the development phase of our gear also has minimal impact on the planet.

All our discarded gear (boards broken on rocks by our team riders for instance) are given to NoK Boards, a company based in Grenoble, French Alps, who specialised in product upcycling. They create brand new amazing-looking longboards from recycled snowboards. This way, we minimise our waste and allow our boards to have a second life, this time on the road.

When it comes to security and environmental practices, our main factory is exemplary: on-site water treatment, core and base trims recycling, regular inspections, etc. For workers: gloves, ear plugs, eye protction and more.

Women are paid the same salary as men | Workers have to take at least 1 day off/week | Workers' health and security is guaranteed | Regular inspections